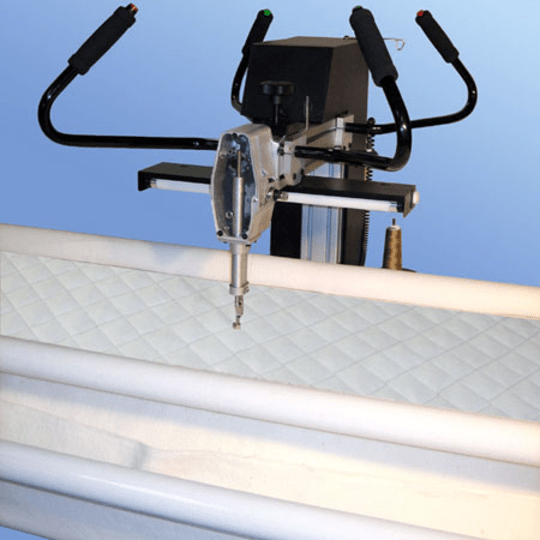

Description

360-degree Motion Control

Driven Presser Foot

Automatic Needle Up/Down

Front and Rear Adjustable Control Handless

Adjustable Speed Control

Laser Pointer

10 foot Steel Frame & Top Handwheel

Table & Servo Motor (Table Comes Assembled)

Applications

- Free arm quilting and embroidery of light and multilayer materials

- Especially suitable for long and complex materials.

Features:

- Light weight aluminum alloy construction.

- Miniature PLC easily adjusts the sewing speed and needle stop position.

- Front and rear adjustable control handles

- Ten foot frame with dual rail easy roller system.

- Adjustable fabric ratcheting tensioners for multi-ply (3) applications.

- Detachable laser pointer for tracing pattern.

- Work table for small patterns.

- Built-in Fluorescent light.

- Nylon wheels with sealed steel bearings.

- 1-1/2 inch 11ga steel poles for less bowing.

- Rotary thread tensioner.

- Oils needle and presser bar for no oil drips.

- Synchronous belt drive to top and bottom shaft.

- Harmonic balancers on top shaft.

- Top mounted non-engaged hand wheel.

- "L" bobbin case and belt driven Koban hook assembly (Model 1709Q) ("M" size bobbin in the 2611BQ)

- Rear mounted thread stand.

- Includes light frame for mounting overhead light (light not included)

Specifications:

|

Motor:

|

5/8 hp 4-pole brush DC |

|

Speed:

|

0-3000 spm |

|

Frame:

|

10 foot 1-1/2 in. 14 ga. steel square tubing |

|

Capacity:

|

1709Q: 17 in. depth x 9 in. height 2611BQ: 26 in. depth x 11 in. height |

|

Voltage:

|

115vac |

|

Shipping Data:

|

Frame 290 lbs / 10' length x 13" width x 10" height Machine 85lbs / 34" length x 26" width x 28" height |

Motor Options

With so many options available for motors when we talk about replacing or buying a motor for our industrial sewing machine, there is one important point to keep always in mind "The Speed". Regardless of brand or price, motors come in two different configurations:

- 1. Fixed-Speed Clutch Motor

- 2. Adjustable-Speed Servo Motor

Clutch motors operate at a fixed speed, typically between 1725 - 3450 rpm, depending on the type of machine. Servo Motors on the other hand are speed adjustable. The two major advantages of the Servo Motor are that you can control the speed of the motor and that the motor is completely silent when the pedal is not engaged.

Some other advantages of the Servo Motor include:

- They consume up to 90% less energy than clutch motors

- 1/3 lighter than clutch motors

- Reverse motor rotation with the flick of a switch

- Nothing to wear or adjust

- Adjusted speed remains the same no matter how hard the pedal is pressed

Most of our customers find that the sewing machine is much easier to control with a Servo motor because of the speed control. This is especially helpful for beginner sewers but also for projects that simply don't require high speed stitching.